5. Club Face

a. General

Interpretation of Rule 5.a

5.a(1) - Spin

If claims of excessive spin are made by the manufacturer, or if there is strong supporting

evidence of excessive spin, then the club would be deemed to be non-conforming.

5.a(2) - Hardness

The “hardness” provision is particularly relevant to putters, many of which have a

urethane or other “soft” material inset in the face.

The measure for hardness is made using a durometer. A putter face must be no less

than 85 on a Shore A scale durometer. A simple measure of hardness in the field would

be to use a fingernail. If a fingernail leaves a significant imprint in the face of

a club, it is possible that the material does not satisfy the “hard and rigid” requirement.

The face of a wood or iron club must be substantially harder than a putter face, i.e.

no less than 75 on the Shore D scale.

5.a(3) - Rigidity

In the field, “rigidity” is interpreted to mean that the face should not have any

visible signs of movement or flex when manual pressure is exerted.

5.a(4) - Concavity

Where there is an inset in the face of the club, it should be flush with the rest

of the face so that the face can still be considered smooth with no concavity. While

we interpret concavity in this provision strictly, we also recognize that, due to

manufacturing tolerances, it is sometimes difficult for every insert to be exactly

flush with the rest of the face. As a result, we allow an inset to be up to 0.006

inches (0.15 mm) proud of the rest of the face or no deeper than 0.004 inches (0.1

mm) below the rest of the face.

b. Impact Area Roughness and Material

Interpretation of Rule 5.b

5.b(1) - Definition of “Impact Area”

Irons

For iron clubs, the “impact area” is deemed to be that part of the club face where

a treatment has been applied (for instance grooves, sandblasting, etc.) or the central

strip down the middle of the club face having a width of 1.68 inches (42.67 mm), whichever

is greater.

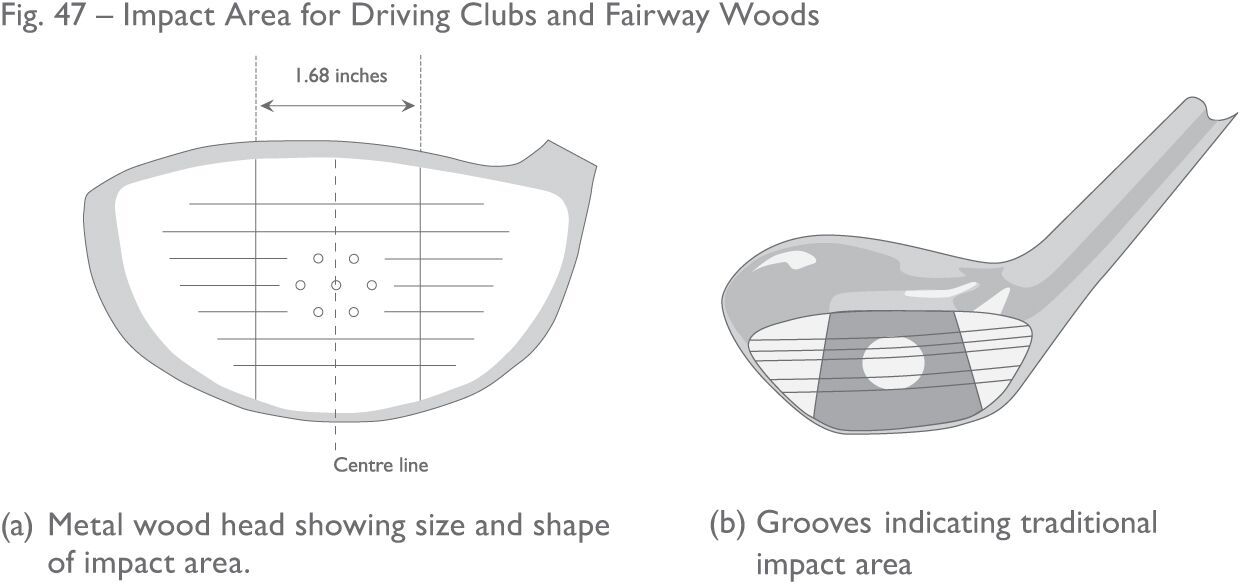

Woods

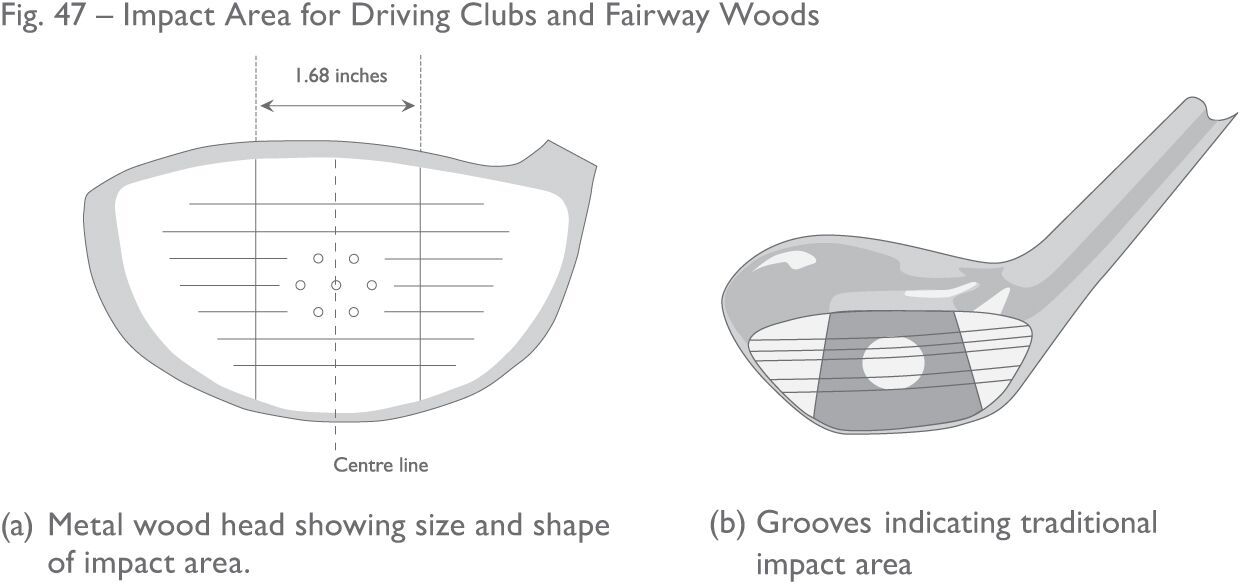

The impact area on driving clubs and fairway woods is deemed to be the central strip

down the middle of the clubface having a width of 1.68 inches (42.67 mm) – see Figure

47a.

NOTE: Grooves and/or punch marks indicating a traditional impact area (see Figure

47b), or any groove which encroaches into the heel or toe portions of the impact area

by less than 0.25 inches (6.35 mm), will not be considered to be within the impact

area. However, any such markings must not be designed to unduly influence, or have

the effect of unduly influencing, the movement of the ball.

For clubs with insets in the face, the boundary of the impact area is defined by the

boundary of the inset, as long as any markings outside the boundary do not encroach

the impact area by more than 0.25 inches (6.35 mm) and/or are not designed to influence

the movement of the ball.

Moreover, the inset itself must extend to at least 0.84 inches (21.34 mm) either side

of the centre line of the face and to within at least 0.2 inches (5.08 mm) of the

top line and leading edge of the face.

IMPORTANT NOTE:

The above definitions of the impact area only apply to models of clubs manufactured

on or after 1 January 2010. For clubs manufactured prior to 1 January 2010, please

refer to the end of Supplementary Paper B.

5.b(2) - Impact Area Roughness

When dealing with the surface roughness of a club face (not including putters, see

Section 5f), the claims made by the manufacturer must be taken into account – especially

if there is a claim that the roughness of the face influences the movement of the

ball. In the absence of such claims, the ruling is made purely on the amount of roughness

there is. Sandblasting or other treatments of roughness greater than 180 micro inches

(4.5 µ metre) are not permitted. In addition to this requirement for roughness, milling

is not permitted if the crest to trough depth exceeds 0.001 inches (0.025 mm). A reasonable

tolerance is allowed for both of the above measurements. Non-conforming sandblasting

or milling usually feels rough to the touch.

5.b(3) - Impact Area Material

The requirement that the whole of the impact area must be of the same material does

not apply to clubs made of wood or putters (see Section 5f). The reason why it does

not apply to wooden headed clubs is to allow the continued use of traditional wooden

clubs which have plastic insets and brass screws in the centre of the face. This design

was commonly used in the old persimmon woods, some of which may still be in use. It

is worth noting that a club face or inset made of a composite material would be considered

to be of a single material and, therefore, would not be contrary to this provision.

Metal wood club faces which have insets of different material not trapezoidal in shape

may be permitted if the height of the inset meets the definition of the impact area

and the width of the inset is the same as the height in at least one point. However,

in order to preserve the intent of the “same material” Rule, clubs which have unusually

shaped insets of different material (i.e. other than circular, oval, square or rectangular)

would not normally be permitted.

If an inset of different material is permitted under the above guideline, the inset

would be considered the impact area for that club. Therefore, any markings outside

that area need not conform to the specifications in Section 5c. However, such markings

must not be designed to unduly influence the movement of the ball.

c. Impact Area Markings

Interpretation of Rule 5.c

5.c(1) - General

The groove and punch mark specifications were updated in 2010 and many pre-2010 models

of clubs do not meet the new specifications. The above Notes mean that the vast majority

of golfers can continue to carry clubs manufactured prior to 2010 until at least 2024.

Supplementary Paper B sets out guidance on how to measure width, depth and separation

of grooves using the ‘ink and scratch’ method and how to determine the conformance

status of a club to the pre-2010 Equipment Rules. This is an adequate method for use

in the field where the Committee has not introduced the Groove and Punch Mark Model

Local Rule (i.e. at the non-elite level).

There are several methods which can be used to measure grooves and punch marks against

the updated specifications detailed above – most of which require specialized equipment.

Full details of the procedure for measuring club face markings and determining their

status against the post-2010 specifications can be found on The R&A’s and USGA’s websites.

A summary can also be found in Supplementary Paper C.

As noted, The R&A and USGA do not recommend adoption of the Model Local Rule G-2 unless

the competition involves professional-level players and/or players at the highest

levels of amateur golf. In order to assist players and officials to determine whether

a player’s clubs meet the condition, The R&A and USGA have compiled an informational

database of irons, wedges, fairway woods and hybrids that have been submitted to either

organization and evaluated for conformance to the updated specifications. This information

is available on The R&A’s and USGA’s websites, respectively.

Notably, clubs where the face markings have been purposely altered, for example, by

re-grooving must conform to the 2010 groove and punch mark specifications. However,

clubs which have only been refurbished back to their original state (perhaps by light

sandblasting) may still benefit from the period of grace given to pre-2010 models.

For the avoidance of doubt, all new models available after 31 December 2009 must conform

to the current Equipment Rules.

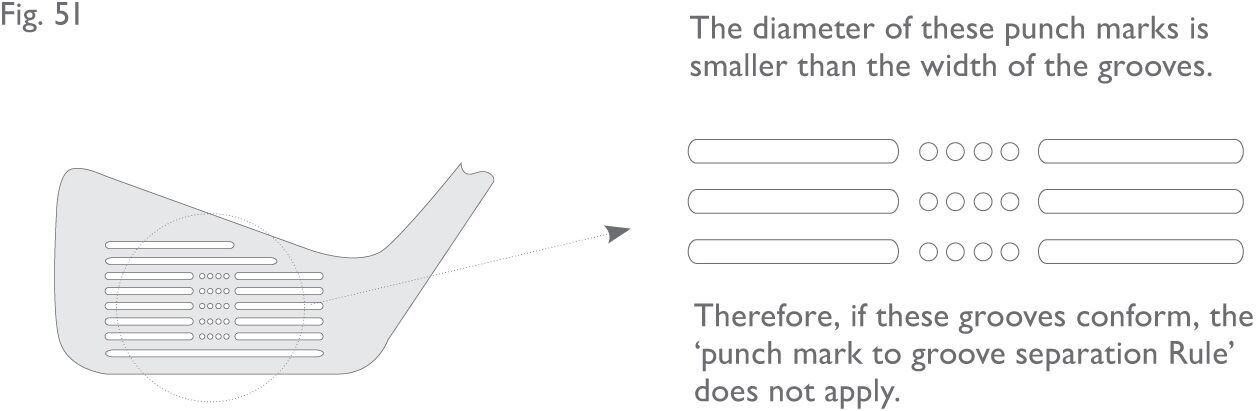

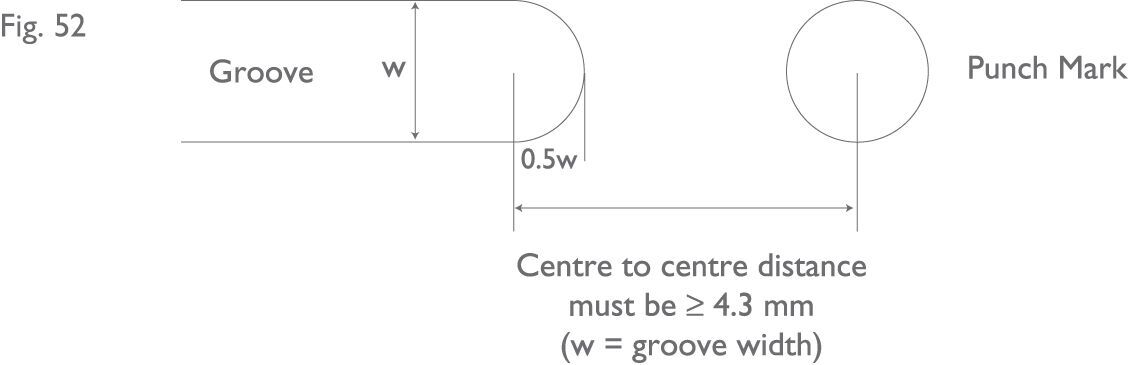

5.c(2) - Groove/Punch Mark Combinations

If punch marks are used in conjunction with grooves, the following guidelines apply:

Iron Clubs

-

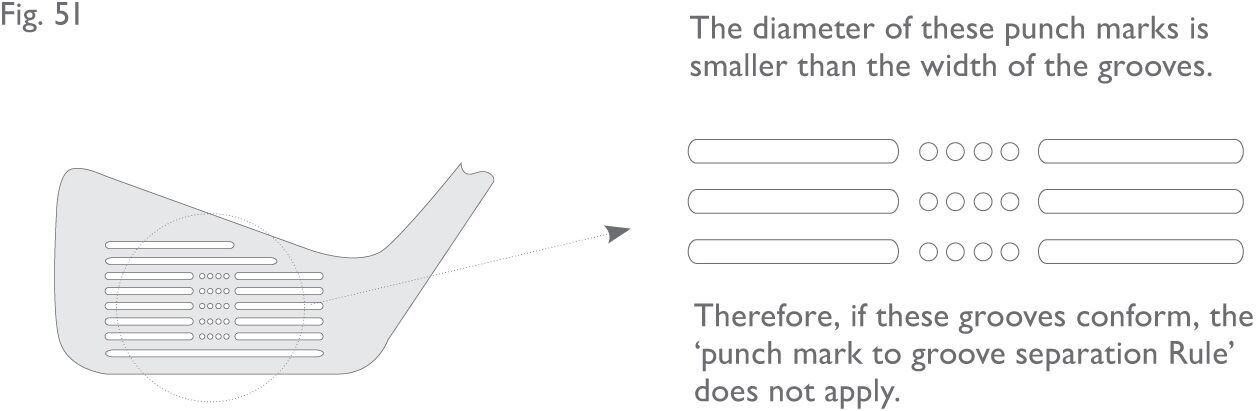

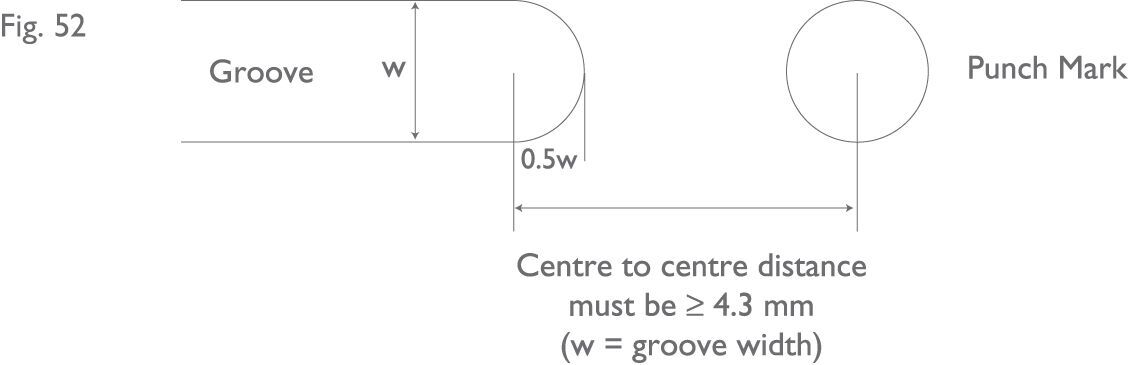

Small punch marks which are in line with a conforming groove, and which would be totally

contained within a continuation of the groove do not have to meet the punch mark to

groove specifications (See Figure 51). However, if the diameter of such punch marks

exceeds the width of the groove, then they must meet the specifications.

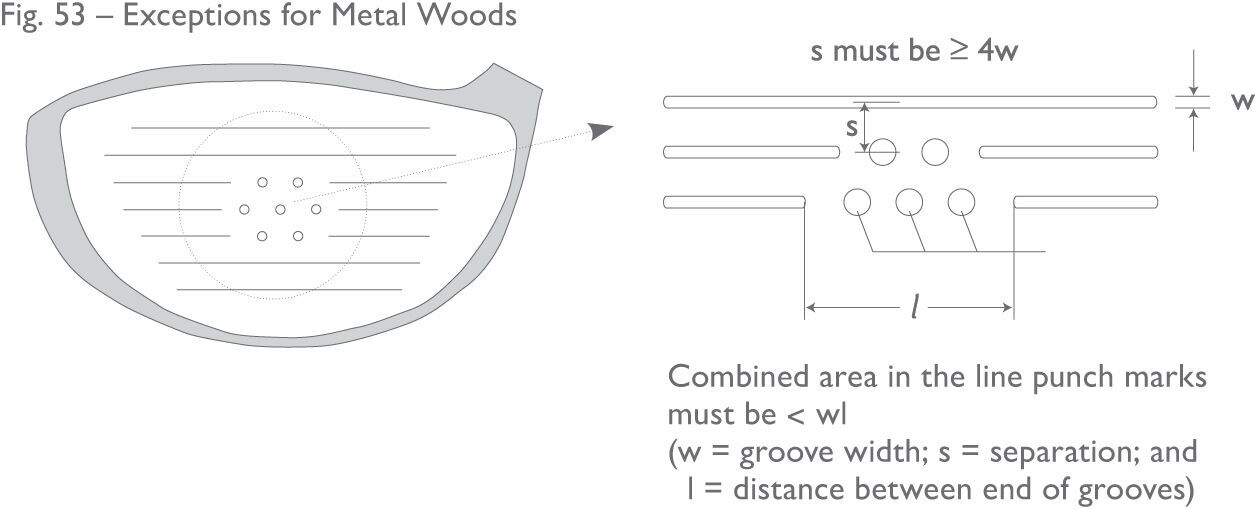

Metal Wood Clubs

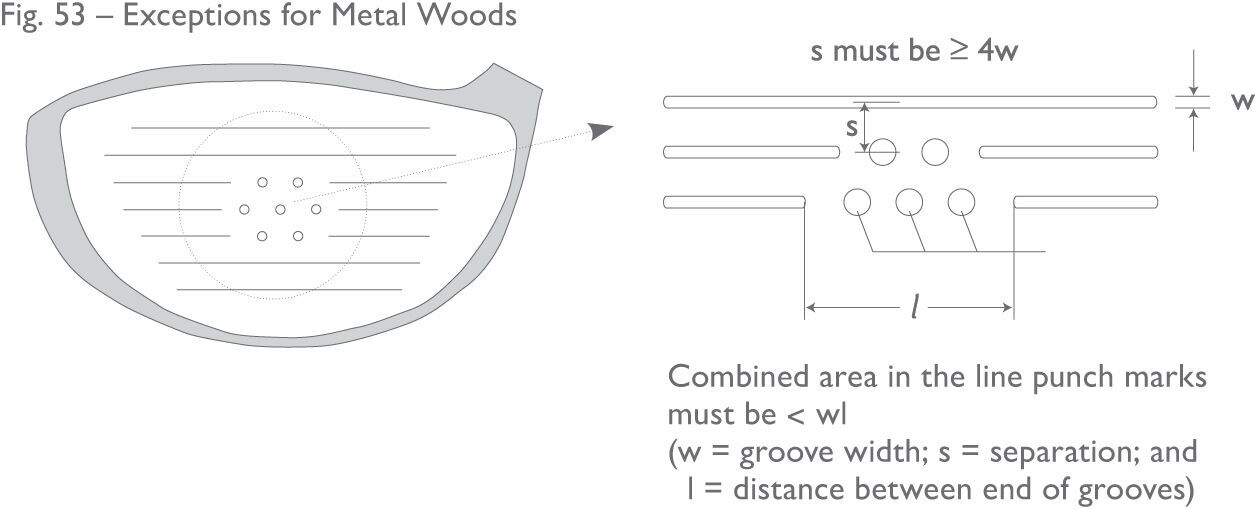

Provided the following three conditions are satisfied, the above interpretation of

the specifications for punch marks in line with a groove may also be granted for metal

woods, even if the punch marks would not be totally contained by the continuation

of the groove:

-

there must be no more than three in-line punch marks in the part of the groove that

is missing (i.e. in the gap between the ends of the partial grooves);

-

the combined area of all of the in-line punch marks in any one such gap must not exceed

the area of the missing groove; and

-

the separation of the in-line punch marks from adjacent parallel grooves – measured

from centre to centre – must be at least four times the width of the groove.

Fig. 53 illustrates each of the above conditions:

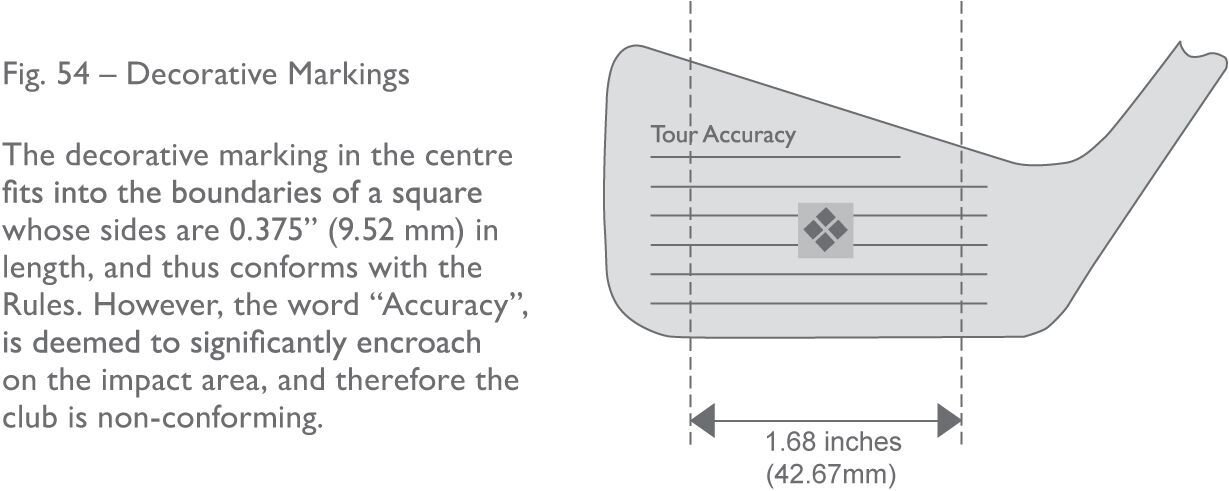

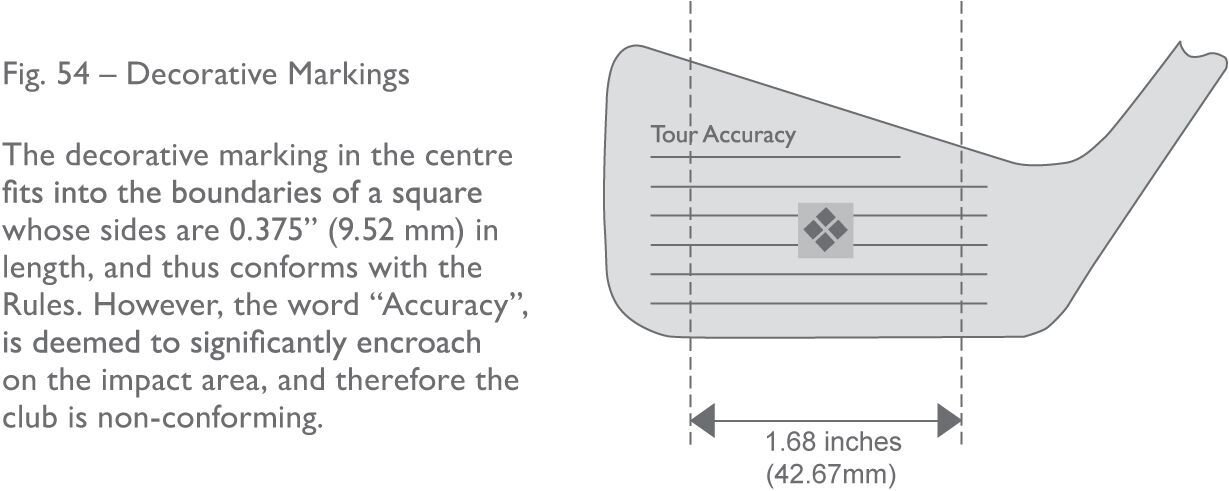

d. Decorative Markings

Interpretation of Rule 5.d

This provision permits small, decorative logos in the centre of the face or at the

side of the impact area (see Fig. 54). Decorative markings or logos that marginally

encroach on the impact area, i.e. by less than 0.25 inches (6.35 mm), may be permitted.

However, any such markings must not be designed to unduly influence or have the effect

of unduly influencing the movement of the ball. Markings outside the impact area which

are designed to influence the movement of the ball when it has been mis-hit would

be contrary to this provision.

f. Putter Face

Interpretation of Rule 5.f

In addition, if a groove or the grooves on the face of a putter exceed 0.035 inches

(0.9 mm) in width and 0.020 inches (0.508 mm) in depth, the following guidelines apply:

-

The width may not exceed 0.060 inches (1.524 mm);

-

The width to spacing ratio must be no less than 1:1; and

-

The depth must be less than the width, and may not exceed 0.040 inches (1.016 mm).